The energy management system is designed to reduce energy consumption, improve the utilization of the system, increase reliability, predict electrical system performance, and optimize energy usage to reduce cost.

Energy Management system is the combination of the Hardware and Software which helps to:

Monitor: Monitoring the regular consumption of the Energy and checking any deviation from the target.

Analyze: Collecting Data and Analyzing to identify trends as to how energy was used at various production levels of a manufacturing process.

Target: Setting Targets to control the energy consumption according to the need and process.

Control: For meeting Target setting up management and technological measures.

Engagement: By displaying real-time consumption information, user can see the immediate impact of their actions. Letting user to know their real-time consumption alone can be responsible for a substantial reduction in energy consumption.

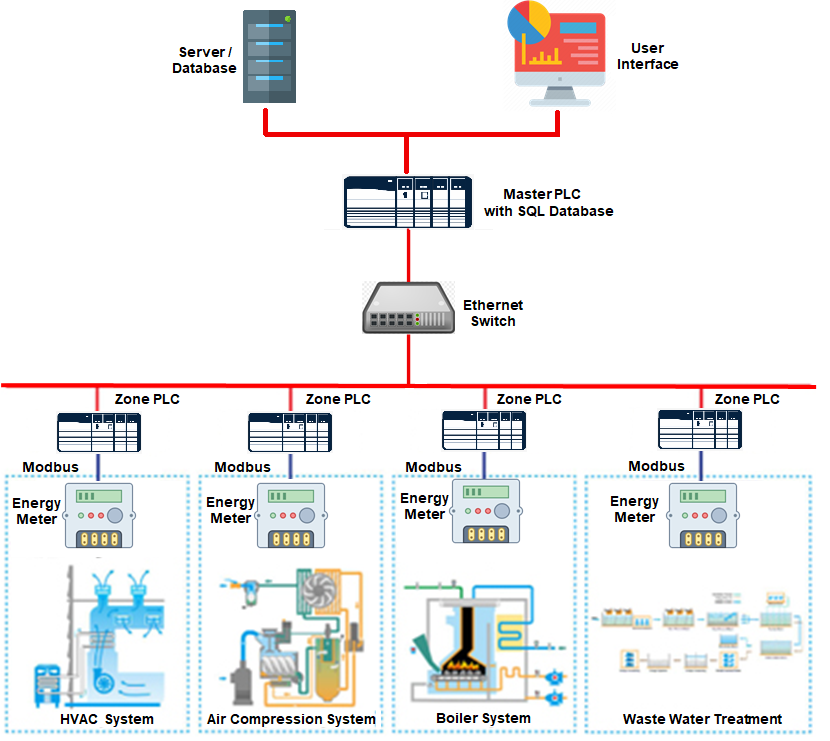

Architecture:

An EMS consists of smart energy meters, sensors and devices that monitor energy consumption and factors effecting consumption. These devices transmit data over wired network to a central server.

To Implement the EMS, we follow the below guidelines:

Features of Software:

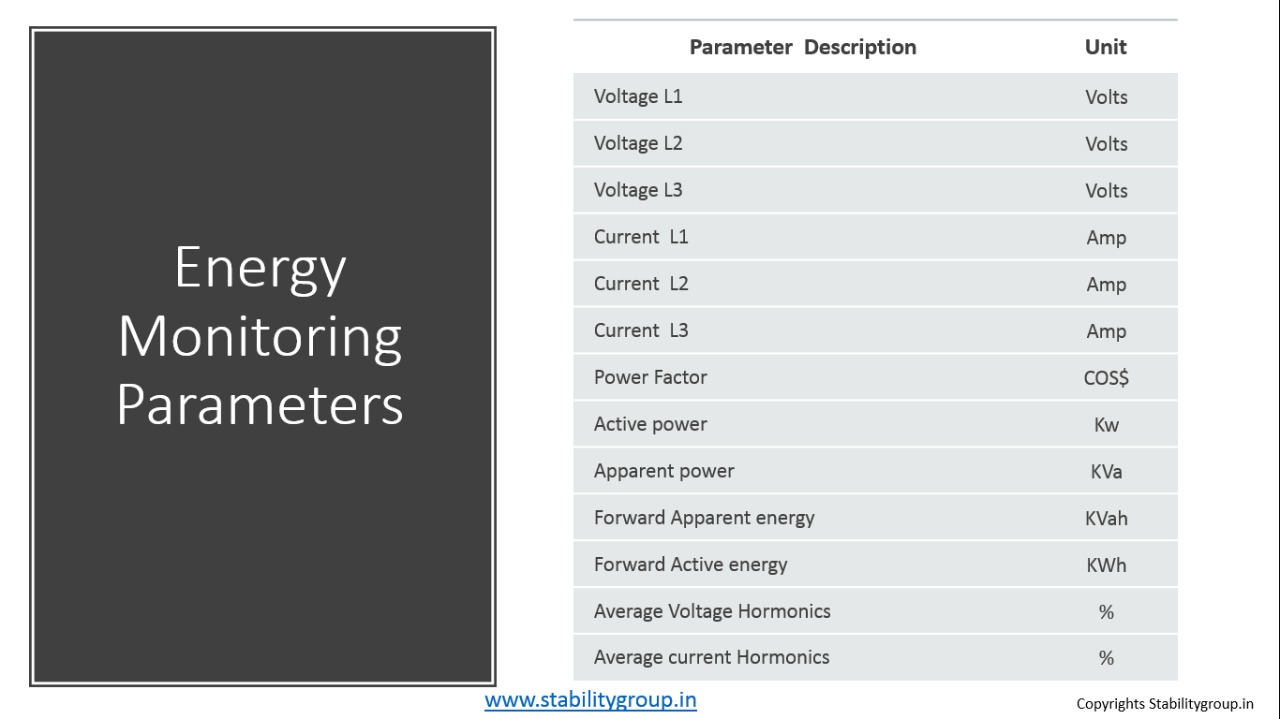

Parameters Measuring:

We have implemented the energy management system in Automotive Industry and total of 243 energy meters are integrated and the Data is collected into the local server. Where whole data is analysed to get a better understanding of energy consumption in the Industry.

Energy Management Systems (EMS) can improve productivity and expand production, while at the same time reduce the energy consumption of production and increase economic efficiency. After implementing an EMS, a company is able to carry out energy planning, energy efficiency, consumption analysis, equipment and system management to help management make faster and better-informed decisions by providing up-to-the-minute information. This lets enterprises reduce overall operating costs, maximize profitability, accelerate growth and increase asset efficiency.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.