The new industrial revolution is changing how manufacturers operate today and plan for the future, influencing a significant transformation in manufacturing, engineering and factory-floor industries. Adding to this, manufacturers are under pressure to meet the demand for faster delivery of new products, coupled with shorter production lifecycles. Organizations are adopting agile, flexible production plant systems and processes to adapt and evolve, so as to remain competitive and profitable. Customers are looking for plants and machines will have to be smarter, better connected, more efficient, flexible, and safe.

The IIoT vision of the world is one where smart connected asset (the things) with varying levels of intelligent functionality, ranging from simple sensing and actuating, to control, optimization and full autonomous operation, operate as part of a larger system. These systems are based on open and standard Internet and cloud technologies that enable secure access to devices and information in order to leverage big data and analytics and mobility technologies to drive greater business value.

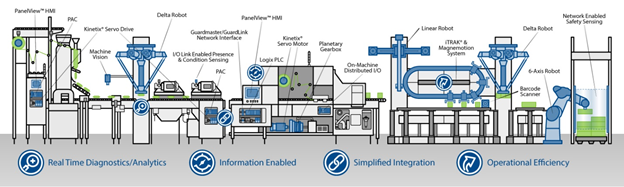

Original Equipment Manufacturers (OEMs) and end users are leveraging IIoT for better monitor and control machinery. Within industrial environments, some devices today are connected, but many are not. IIoT applications will include not only machine-to -machine (M2M) communication but also machine-to -people, people-to -machine, machine-to -objects, and people-to -objects communication. These connections enable the ability to collect data from a broad range of devices and applications.

We Offer wide range of Smart Machine Solutions to Our customers

IoT Enabled Condition Monitoring Solution: Condition monitoring involves measuring variations in indicators such as vibration, temperature, current, flow levels, pressure, etc. This type of IoT-enabled monitoring helps provide insight into the performance, health, and status of connected devices to help manufacturers improve resource utilization and prevent unplanned downtime.

Smart Motor Toolkit: This Smart Motor Toolkit trend is bringing about a fundamental change in the way Motors works, making them safer, more efficient, more flexible and more environmentally friendly.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.