The Vacuum Leak Test is used to determine the air-tight integrity of a pre-vacuum autoclave’s chamber. This test exposes the autoclave’s plumbing and components to vacuum conditions and measures how much vacuum depth was lost over a given period of time.

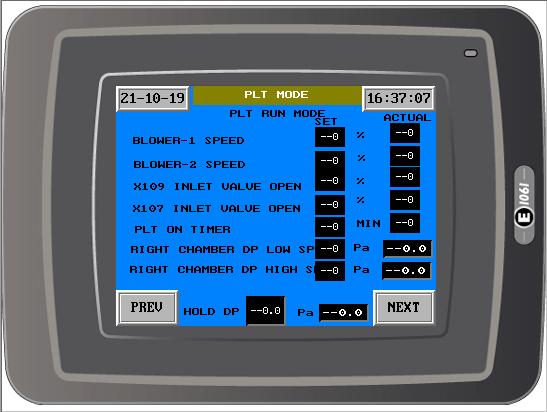

Vacuum leak test machine mainly used to maintain the Vacuum in chamber. The air is allowed through the inlet valves of right chamber and left chamber from the 2 blowers after reaching the pressure set point, inlet valves will close to maintain the pressure at standstill within the chambers. After that through the outlet valve whole air is passed out and only vacuum will be present. The vacuum is maintained without any air allowed in the chamber.

The pressure has to be maintained constant within the permissible limit in two chambers. By considering the constant pressure, first we need to know the actual pressure and pressure set point. The pressured air is passed into chambers through right and left inlet valves with the help of two Blowers.

If the pressure is not with in the permissible limit a pop-up is displayed in the HMI, indicating as pressure leak and the test fail. Need to press stop the process and machine will go through the aeriation mode directly without executing the fogging mode. After the aeriation mode completed the machine come to normal position.

If the pressure is within the limit then it shows as leak test pass and it will ask to continue the process. Fogging mode is activated and blowers and valves will be open. After completion of fogging cycle, automatically machines go into aeriation mode. In aeriation mode process is also same as fogging mode but the difference is blowers speed and inlet valves open position which are set in individually. Finally, the machine will go into the run mode.

In vacuum leak test machine, the vacuum is allowed into the chamber and the cycle will start. The permissible limit of vacuum leakage is 0.013bar. And the whole range of vacuum is -1 bar to 5 bar. After cycle starts the stabilizing time, holding time, brake pressure stages will occur. After the brake pressure the vacuum leak test is going to judge whether the test is pass or failed.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.