Angle Board Cutting Machine is used to make angle board from paper & cut the material with predefined specific lengths, all this synchronization of conveyor, gluing & forming done automatically using PLC based Automation. Mainly angle boards are used in material packing to protect the material from all sides.

Angle Board Cutting Machine mainly having one Reel Holding stand, Cascade Gluing System Forming & In-Line Cutting. Reel Holding stand is used to hold and feed the paper properly into Glue Cascade system. It is made of MS angles and flats. It has bottom rollers to adjust to any position during operation.Cascade Gluing System: It is used to transfer the Glue from Glue tank to paper layers properly. In this system, there will be a Glue tank & boil the Glue by means of electric heaters, Glue will be pumped to Paper layers by Pump. Paper tension arrangement, Glue supply system and glue scrapper system to remove excess glue provided.

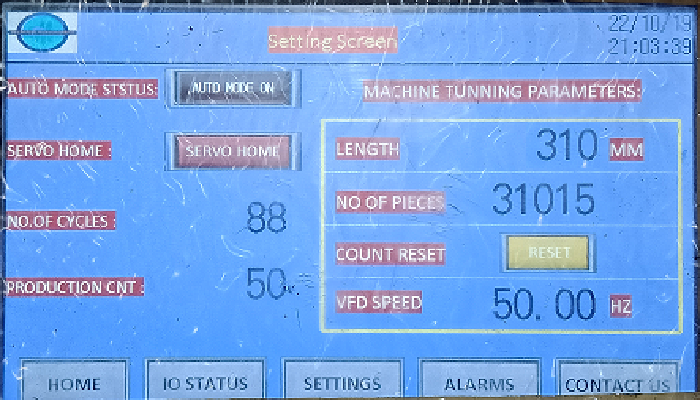

Forming Machine: After Gluing the papers are fed into forming machine which has three stations with big angular female and male rollers operated pneumatically. As the paper is fed through the machine, the angle is formed stage by stage and then it is passed to the shearing system. Rollers are driven by motors with speed control.In-Line Cutting: The formed edge protector is passed to the online cutter, cutter settings has been done from HMI, It cuts the angle board to the required length, this cutter operated by a Servo System which is actuated by PLC & with encoder feedback for accurate length cutting. Angle board are varies from 1mm to 100mm width depends on length & width servo speed adjustment will done automatically by PLC.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.