Error-proofing refers to the implementation of fail-safe mechanisms to prevent a process from producing defects. There is no mistake – quality is an ongoing, fundamental part of any manufacturing process. It means continuous improvement. It also means that quality is everyone’s responsibility, it’s not just one department or only done at the end of the process. Error proofing devices, referred to as Poka-Yoke devices, such as instruments, need to be integrated into the process with complete traceability throughout. Also, provisions have to be in place to quickly and easily add new Poka-Yoke devices and additional traceability as requirements evolve.

Error-proofing is an excellent activity to involve the workforce in continuous improvement. Many poka-yoke ideas relieve stress from operators by eliminating the need to concentrate on mundane activities and by providing more capable tools to get the job done right consistently.

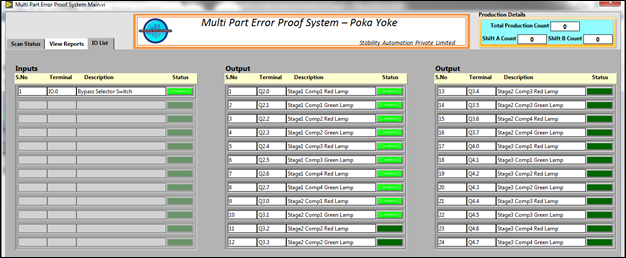

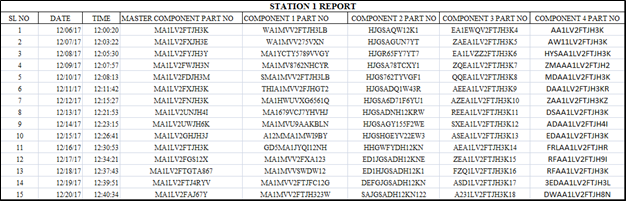

So, in Engine Assembling Line we have implemented Error proofing solution to make sure the correct part is inserted in the correct engine. In this solution we have used PLC, Barcode Scanner and SCADA System. On every stage of the process we have used slave PLC’s which are interconnected to each other and to the Main PLC as well. A barcode scanner is used to make sure, the part which is scanned is assembled in the correct engine. And a SCADA system to monitor the entire process, to give report and to give alarms if the correct part is not assembled in correct engine.

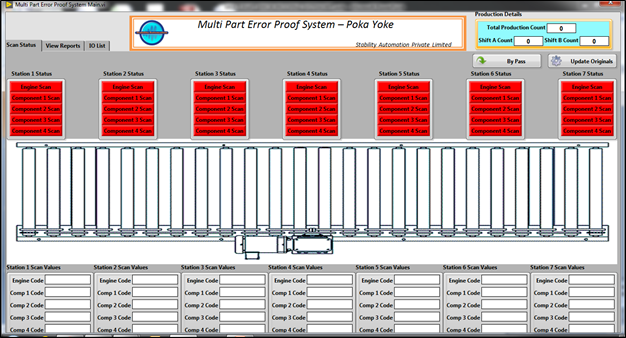

The Features of the SCADA System:

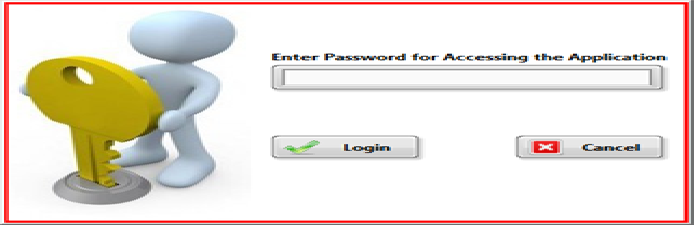

The SCADA is password protected; the user has to put valid credentials to access it.

On the Main Screen, User shall be able to view the:

Error proofing, or Poke Yoke, can greatly decrease defects in processes and increase speed of processes. By decreasing variation and designing a system where the right way is the only way to produce a product or service, error proofing, enables focus on the other variable factors in the process. The more error proofing built into processes, the less the defects associated with errors will be generated.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.