Four Key Differences Between Industrial IoT and SCADA:

The Industrial Internet of Things has assumed an essential part in improving the elements of distant checking. While most organizations have just actualized SCADA frameworks for this reason, the Industrial Internet of Things has step by step supplanted its capacities. Let us assess the difference between the two frameworks.

1. Device Interconnectivity:

While executing SCADA frameworks, binding together gadgets that are made by unmistakable producers is a near outlandish errand. Moreover, when the gadgets are created by a similar producer, it tends to be hard to utilize them reciprocally as their model may fluctuate. They additionally require an even program that can work over a large group of gadgets, independent of their maker or model.

Presently when we assess IIoT, the framework relies upon the idea of interconnectivity. The essential intention of this is to encourage correspondence over various gadgets. Nothing is reliant on the model or producer of the apparatuses. It utilizes techniques like MQTT to encourage excessive correspondence over all gadgets in a complete framework.

2. Operating Expenses & Costs:

So as to store additional information in a SCADA framework, organizations will definitely acquire costs on new workers. Likewise, during the time spent programming permitting or getting extra highlights, SCADA clients need to purchase particular licenses for new administrations and need to habitually pay for redesigning the framework.

The Industrial Internet of Things can enormously alleviate the equipment and programming costs for organizations, while likewise eliminating the prerequisite of truly empowering programming authorizing and redesigning by executing cloud administrations.

3. Data Insights:

While utilizing SCADA frameworks present inadequacies in examining and deciphering notable information, organizations will in general experience these obstacles in investigating old information and afterward deciphering it. SCADA doesn’t zero in on working together or deciphering the information that organizations are producing day by day. The data neither carries any significant bits of knowledge to the clients nor does it offer any pivotal assistance to the leaders of the business.

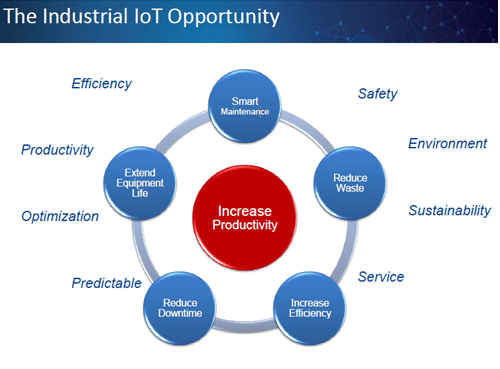

Here, IIoT eclipses its rivals. It solidifies and gathers information from a few business capacities, and afterward in this manner applies large information examination to foresee proficiency and dodge any expected changes. With the complete discernment from IIoT, companies can foresee unanticipated hardware preventions and support necessities.

4. Scalability:

In SCADA programming, there are gadgets that present basic data yet have never been used as they require an overhead cost. Additionally, as the quantity of clients expands, the data transfer capacity ought to likewise be made enormous enough to deal with the expansion which causes security concerns and moderate most issues. Besides, it additionally takes a long effort to set up.

IIoT can acquire and deal with a lot of information, while likewise empowering clients to associate extra apparatuses calm. The entirety of this information is shipped off a cloud and got to utilizing login subtleties. Data or information from anyplace on the planet can be seen and gotten to by means of a HMI framework that associates them to the mists.

In the wake of looking at and assessing the two subjects examined in the article, unmistakably using the advantages of IIoT would be useful over the long haul.