Many industrial enterprises having Business Objective of reduce costs, improve internal processes and increase profitability. These major operative challenges often leave little time for working on innovations. However, this situation makes doing so all the more worthwhile, as digital transformation addresses many of these challenges.

Digitalization is the use of digital technologies to change a plant business model and provide new revenue and value-producing opportunities, it is the process of moving to a digital business.

Every company in every industry will be dramatically affected by the digitization megatrend, and it will be the responsibility of the top teams to lead the charge by building the right capabilities for their companies to remain relevant in the digitized environment, achieve growth, and fend off competitive threats and we help our Customers to achieve their business objective with respect of Digitalization.

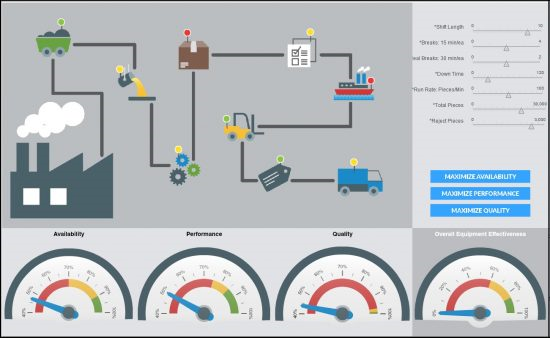

We Provide Digitalization Solutions for Manufacturing from Selection & Installation of sensors based on Application to Analysis of Data to bring Insights and Business benefits.

Digitalization Services we offer:

Assessment of Plant Digitization Readiness: Digital readiness is simply the ease with which employees and organizations can transition to digitized workflows, using software and other technology.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.