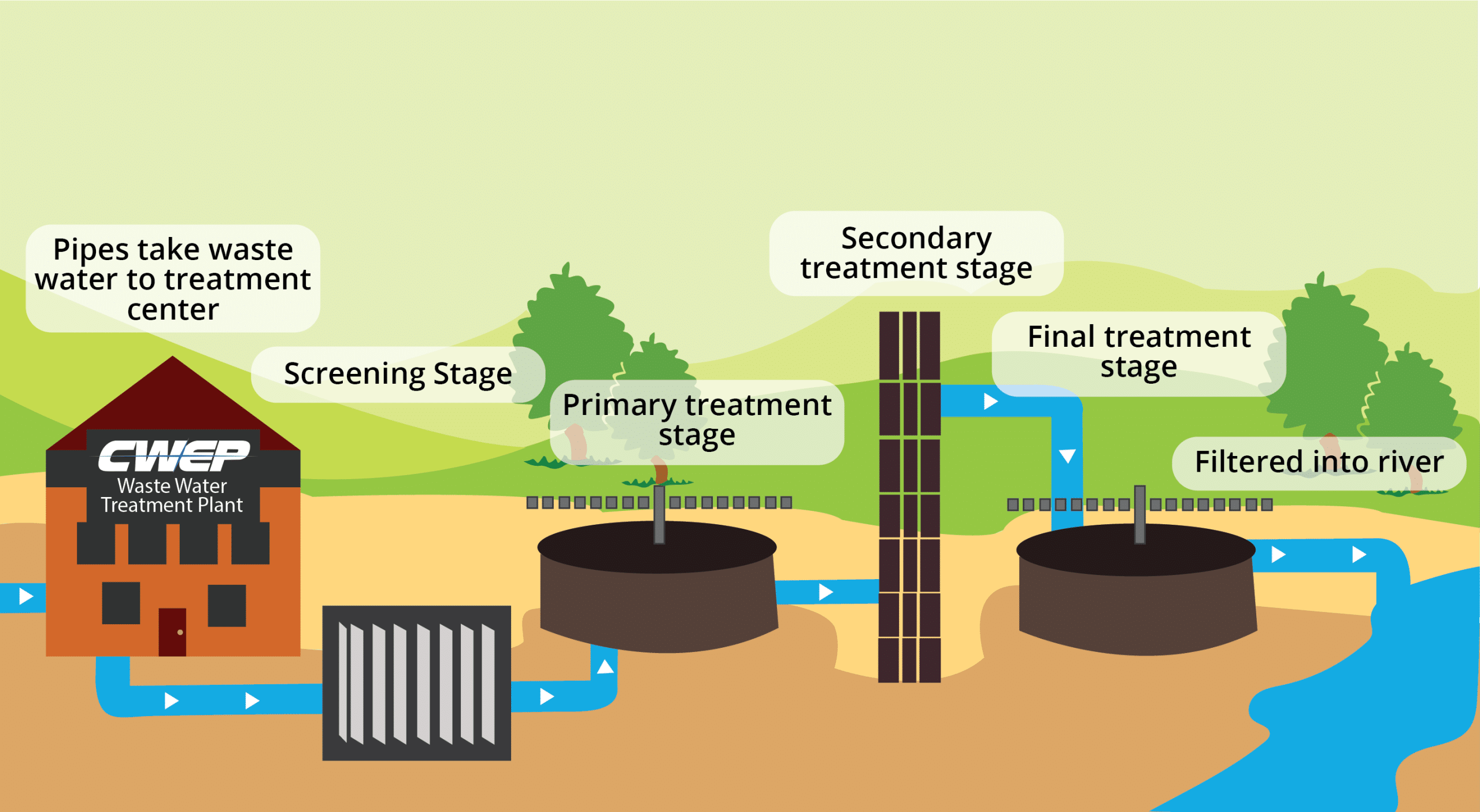

Automatically removes the wastage present in water based on water level. The project has done in two different areas DHANAS and 3BRD 50MBLD Plant.

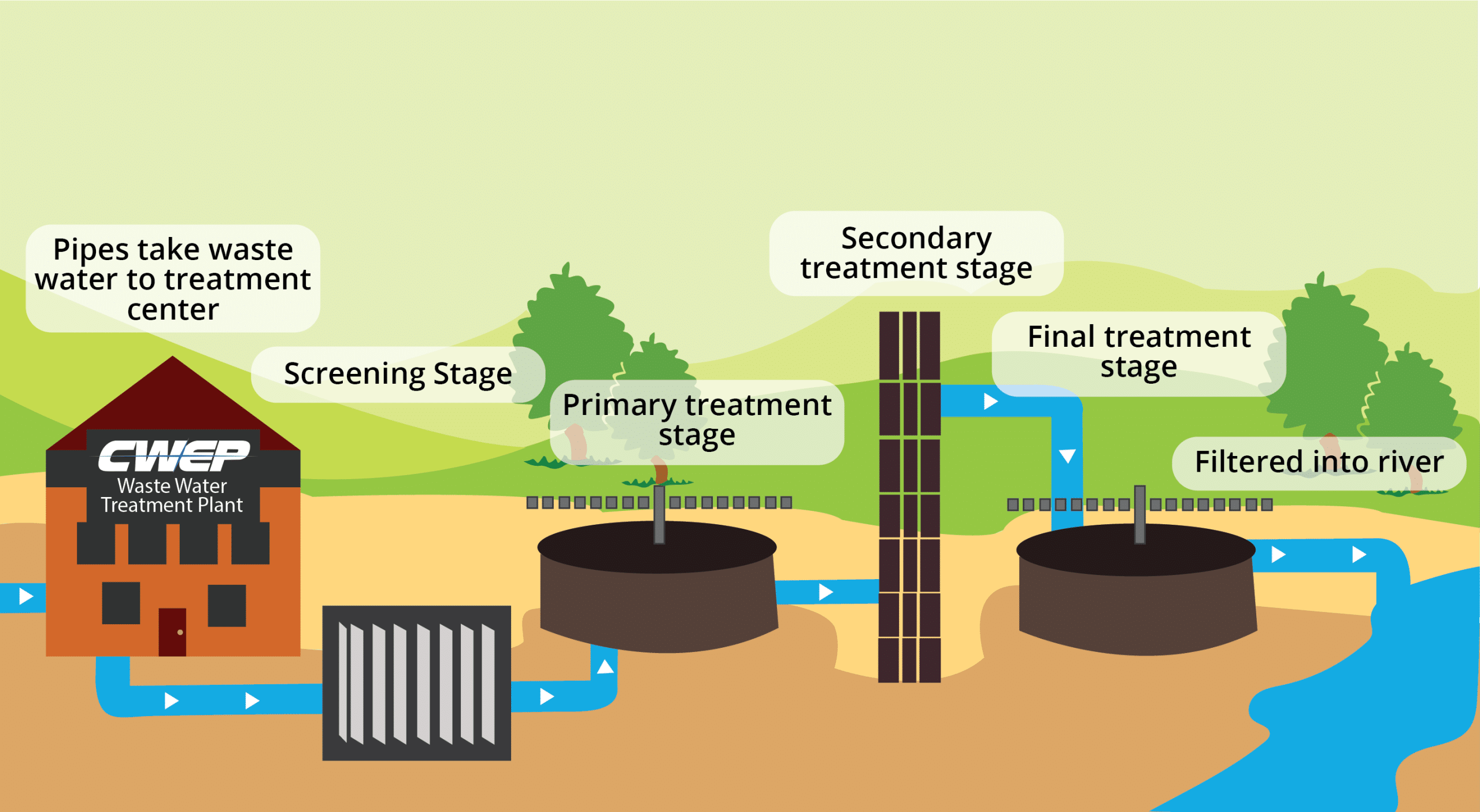

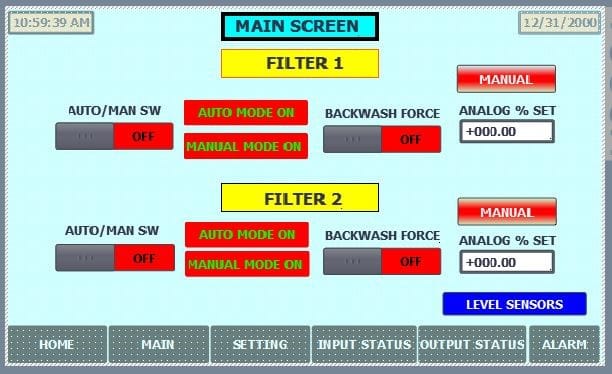

Operator should set the timing for the motor operation. He can access the settings in settings screen. The main screens HMI are

Menu screen: In this operator can access for motor Auto/Manual operation along with Force backwash operation. Navigation button for manual screen also available here. Machine Auto/Manual, force backwash on/off, level sensor percentage difference set selection are also given.

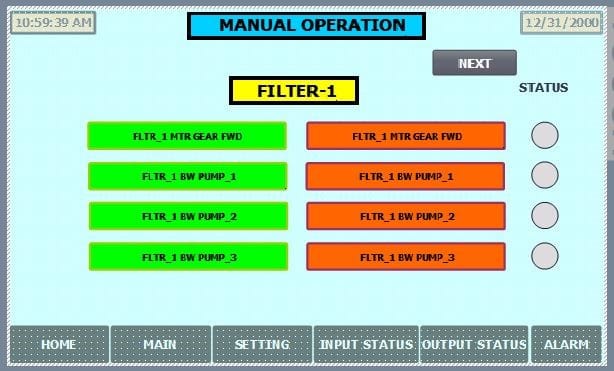

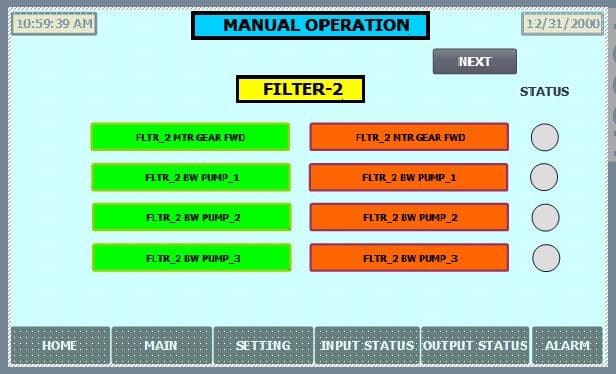

Manual Screen: There are two individual manual screens for each motor operation, filter1 and filter2. Start & Stop buttons were given for each motor.

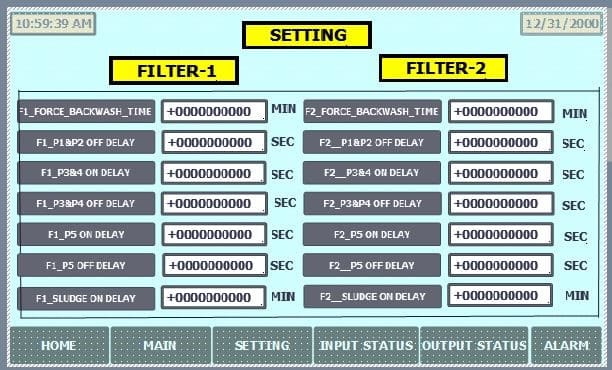

Settings Screen: In this screen, all motor on & Off time setting were given which are used in auto operation.

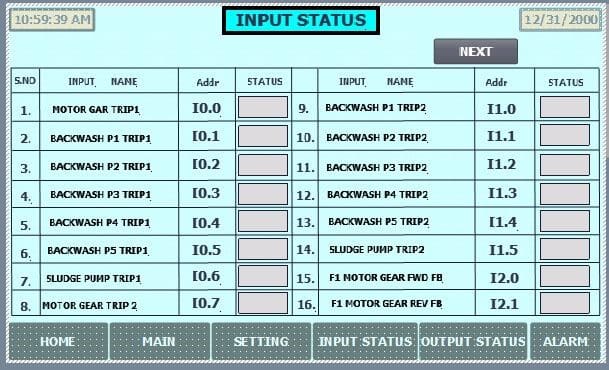

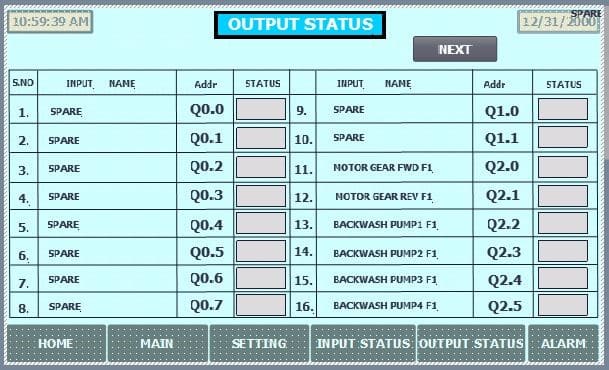

IO Screen: From this screen operator can check which input/output is on/off.

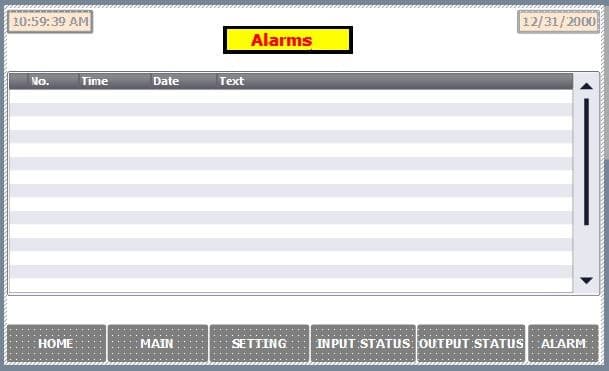

Alarms Screen: In this screen operator can see all motor contactors feedback, trip & PSW alarms.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.

In paper cup manufacturing industry cups counting and packaging manually consumes a lot of time and requires a huge Man-power. Here we have provided a automation solution for the counting of the cups & packaging simultaneously to make the operation faster and accurately. Thus, an Automatic cup counting machine is used.

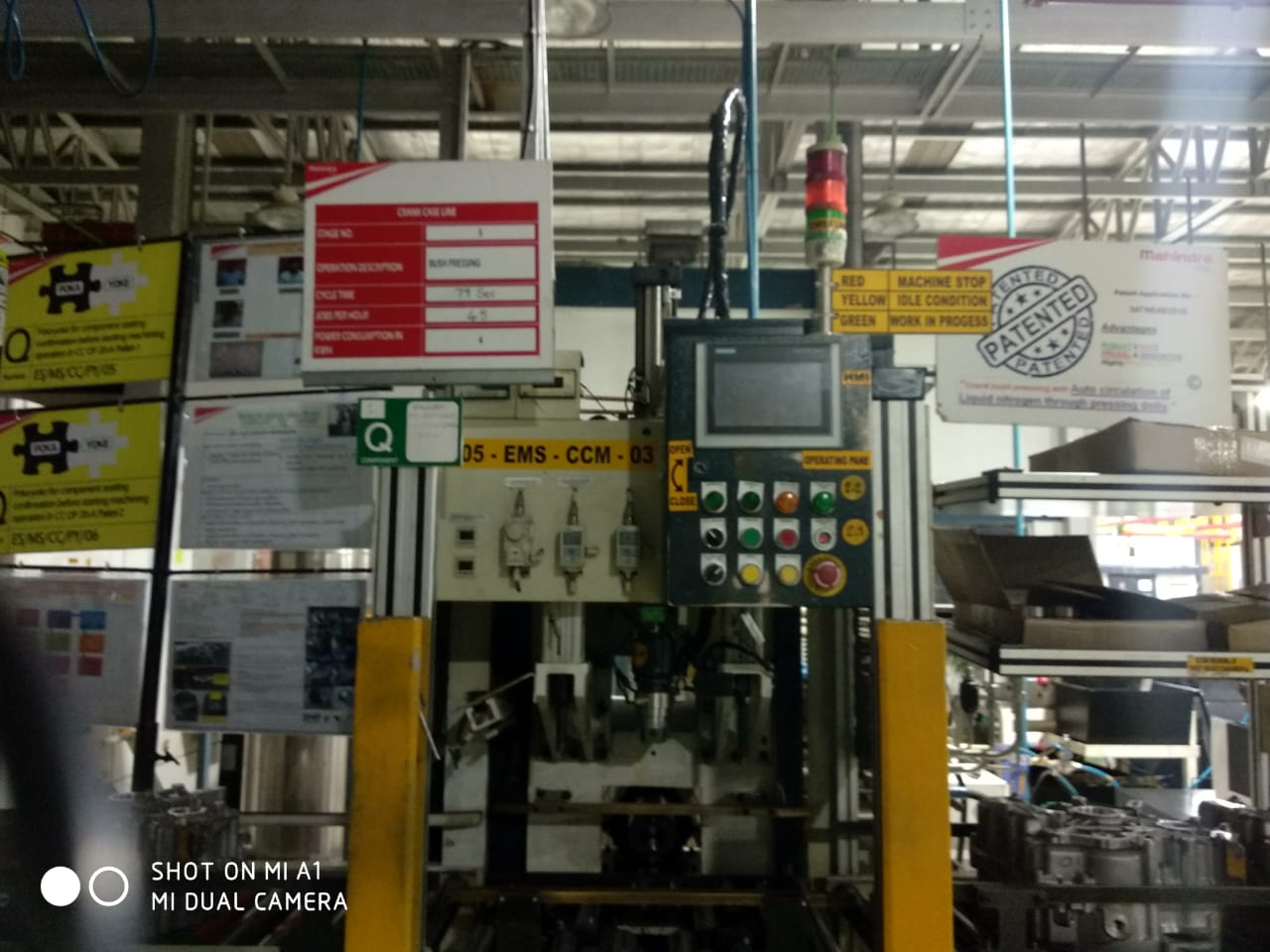

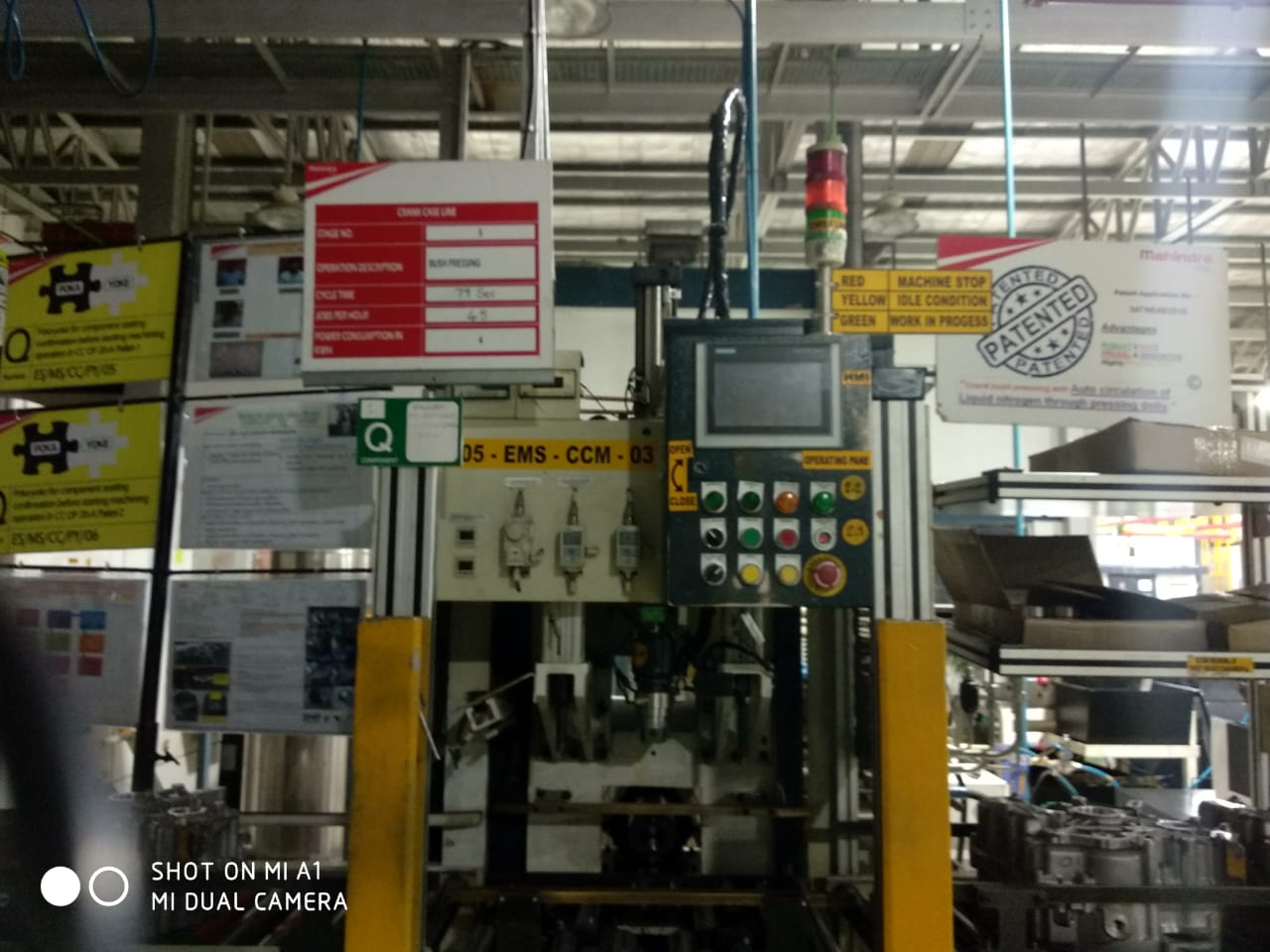

Bush Pressing Machine is used to verify the inner diameter of a cylinder and also the leakages in the cylinder. In this process fixed size of bush will send through cylinder and pass air into the cylinder to check the leakage by measuring inlet and outlet pressure, so that inner diameter of the cylinder will be verified as per quality standard. This process also verifies any leakage of component without visual inspection.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.

In paper cup manufacturing industry cups counting and packaging manually consumes a lot of time and requires a huge Man-power. Here we have provided a automation solution for the counting of the cups & packaging simultaneously to make the operation faster and accurately. Thus, an Automatic cup counting machine is used.

Bush Pressing Machine is used to verify the inner diameter of a cylinder and also the leakages in the cylinder. In this process fixed size of bush will send through cylinder and pass air into the cylinder to check the leakage by measuring inlet and outlet pressure, so that inner diameter of the cylinder will be verified as per quality standard. This process also verifies any leakage of component without visual inspection.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.