Special Purpose Machines are those machines which are not available off the shelf and these are not covered in standard Manufacturing process, these are designed and tailored made as per the customer specific requirements.

Continuously in the production cycle there is a since quite a while ago felt need to improve the nature of item, limit dismissal and increment the efficiency per individual, to take into account the squeezing conditions in the globalized world economy.

A large portion of the Special Purpose machines are centered around automated trimming or inspection, and assembling operations. Organizations plan and production Special Purpose machines for material ventures, machine instruments, jewel businesses, esteem expansion machines, and related machines for different fields.

Different layouts of SPM

There are two layouts for SPMs:

- Single-station

- Multi-station

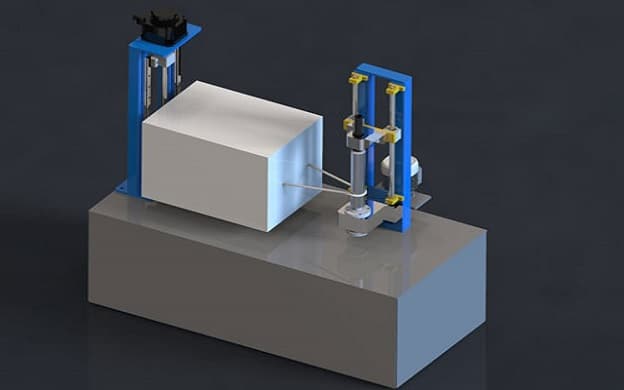

In single station the workpiece is held in a fixed position where machining and sliding units are situated around it with the end goal that they can handle the part from various headings.

On account of different machining units, they may deal with the part at the same time or in grouping relying upon the math of the workpiece and machining highlights

Different layouts for SPMs; (a) Single-station, (b) Special application, (c) Transfer machine, (d) rotary machine, and (e) In-line operation machine.