1. Smart Manufacturing:

Keen assembling is a wide idea; it isn’t something that can be executed in a creation cycle legitimately. It is a blend of different advances and arrangements which altogether, whenever actualized in an assembling environment, is named shrewd assembling. We call these advancements and arrangements “empowering influences,” which help in improving the whole assembling cycle and subsequently increment in general benefits.

A portion of the conspicuous empowering influences in the current market situation include:

- Artificial knowledge

- Blockchain in assembling

- Industrial web of things

- Robotics

- Condition observing

- Cyber security

Organizations are continually contributing and investigating how to acquire benefits through the usage of empowering influences. On the off chance that we intently take a gander at empowering influences, at that point we will see that they are either producing information, tolerating information, or both. Information investigation will help in making the creation cycle effective, straightforward and adaptable.

2. How Data Drives Smart Manufacturing

Keen assembling is tied in with saddling information; information will let us know “what to do” and “when to do it.” Since shrewd plants are worked around information, digital protection, most importantly, will play a significant and critical function in the whole environment of savvy fabricating. Information security is a significant test while executing these empowering agents.

All the partners of brilliant assembling might be portrayed normally in three kinds of organizations which can comprehensively be classified “item and control arrangement suppliers,” “IT arrangement suppliers or empowering agents,” and “network arrangement suppliers.”

Item and control arrangement suppliers incorporate all the organizations associated with the improvement of mechanization items and administrations.

IT arrangement suppliers or empowering agents power the entire idea of IIoT and resource the board. They help in building control, observing and investigation foundations.

Availability arrangement suppliers are telecom specialist organizations that encourage the smooth progression of information for resource the board

3. Usage of IIoT:

Modern web of things (IIoT) is only an environment where each gadget, machine or potentially measure is associated through information correspondence frameworks. Each machine and bit of mechanical gear is implanted or associated with sensors which regularly create the important information. This is additionally moved to the cloud/programming frameworks through information correspondence frameworks. This colossal measure of information has heaps of knowledge which whenever broke down may help in recognizing certain dull zones inside the creation cycle. After the investigation of the information, it is sent as criticism to the creation frameworks for any restorative activity.

Savvy fabricating isn’t broadly actualized; be that as it may, it’s there in pieces and pieces in certain associations. You can’t change the fundamental plan of machines or a processing plant framework to actualize every one of those sensors and other related innovation.

4. Ascent of Artificial Intelligence (AI) in Manufacturing

The idea of computerized reasoning is old, however it is presently discovering applications in assembling environments. In the last 5-6 years, there has been an enormous increment in premium and speculation with respect to AI in assembling. This is primarily because of a couple of reasons, as AI will work just if the information is accessible, and it has as of late been conceivable to fabricate the required ability to:

- Generate enormous measure of information with ease sensors

- Store information in ease frameworks

- Process information at reasonable rates

These have altogether made it feasible for AI to be actualized in assembling shop floors. Prior assembling was being finished by ease nations where it is hard to legitimize the significant expense of usage of AI in their assembling biological systems

The developing use enormous information innovation, modern IoT in assembling, broad utilization of advanced mechanics in assembling, PC vision innovation in assembling, cross-industry associations and coordinated efforts, and critical increment in funding speculations will move the development of the AI in assembling market.

5. Fate of Blockchain in Manufacturing

Blockchain in assembling is still at an exceptionally beginning stage; nonetheless, it is a much-examined new innovation in assembling biological systems. At present, it is being actualized in budgetary frameworks, yet organizations are investigating its application in assembling.

Taking a gander at the abilities of blockchain, flight, food and drink, and clinical are a portion of the enterprises which could extraordinarily profit by this innovation. These enterprises, because of some tough standards and guidelines, require full investigation of every one of their providers over the worth chain. Blockchain could help in keeping up quality control directly from the advancement of crude materials. Presently, a large portion of the consideration is on the improvement of blockchain for flexibly chain work over the assembling environments.

The blockchain market in assembling presently can’t seem to conceptualize completely, and consequently we are anticipating that the market should begin creating noteworthy income from 2020 onwards. In any case, numerous associations have just begun contributing and investigating the advantage from blockchain innovation in assembling environments.

6. Significance of Industrial Robotics

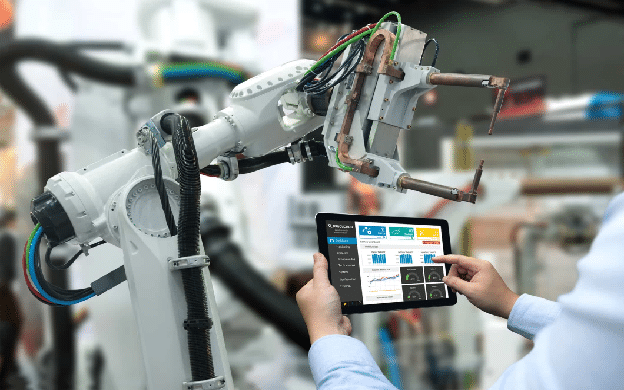

The following thing that makes a regular assembling plant a brilliant assembling office is the usage of mechanical robots. Mechanical robots is certainly not another idea, it has been in the frameworks for the last 40-50 years. The main thing that has changed concerning modern robots is that they have now gotten astute. Prior the robots were customized to do each single undertaking in turn. In the event that you need to do other kind of errands, at that point you should change the codes.

Presently robots are all around associated with the sensor network executed inside the assembling shop floor, and they get the information from sensors and change their activity as needs be. Man-made brainpower is additionally being gradually executed in advanced mechanics frameworks, and consequently it makes frameworks self-ruling. Through AI, advanced mechanics frameworks are relied upon to change their activities as per the circumstance consistently.

Aside from modern robots, there is new kind of robot which is rising and is called community robots. These machines will work close by people to help all the work done by people. For instance, a community-oriented robot can see what a human administrator at a mechanical production system is doing, gain proficiency with the human’s assignment, and independently begin playing out that equivalent undertaking with precisely the same sort of exactness.

7. Advantages of Digital Twins

Computerized twin is another idea in the environments of savvy fabricating. It makes the virtual model of an advantage, cycle, or framework by utilizing the information acquired from sensors in the frameworks or resource and calculations for making sensible projections about the cycle. Prescient support is one of the significant frameworks which will utilize computerized twins. The advantages of computerized twins remember likely decrease for time and cost of item improvement and end of spontaneous vacation. The rising selection of IoT and cloud stages, and 3D printing and 3D recreation programming are boosting the reception of advanced twin.

Aviation and protection, car and transportation, hardware and electrical/machine assembling, and energy and utility are the significant adopter of computerized twins. When the idea of computerized twins creates and develops, at that point we may see its expanding application in non-fabricating areas, for example, retail and the shopper merchandise market.