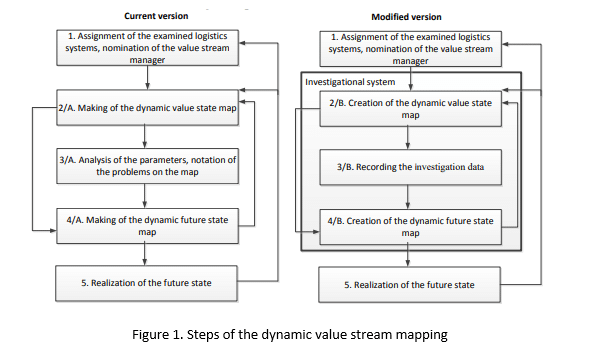

The basic method can’t be used with appropriate efficiency in the case of complex logistics systems. We can distinguish the value stream mapping’s two types that are the static and the dynamic value stream mapping’s method. The static value stream mapping can be used effectively at examination of one product line’s processes. The other method can be used effectively at examination of complex logistics systems. The dynamic value stream mapping’s method come to the front because of the increasing complexity of the processes. This method’s steps were clearly determined but the process improvement’s mode and measure are only realized on the basis of trial and error, anticipation, experience. The dynamic value stream mapping’s current and modified versions are introduced on the figure 1. Application of the dynamic value stream mapping is realized according to the next steps:

1. Assignment of the examined logistics systems, nomination of the values stream manager

2(a). Making of the dynamic value stream map

2(b). Creation of the dynamic value stream map

3(a). Analysis of the parameters, nomination of the problems on the map

3(b). Recording the investigation data

4(a). Making of the dynamic future state map

4(b). Creation of the dynamic future state map

5. Realization of the future state

After we have made the task list then we have to make a yearly value stream plan with the following contents:

- scheduling the assigned tasks’ realization,

- responsible(s) for the implementation,

- to be reached target indicators,

- monitoring of the implementation.

The next step is the realization and its control [9]. The value stream mapping contains basically five sequential steps where feedback can occur between the steps in the next cases:

- if the current state map doesn’t contain such information that will be necessary to the future state map,

- if the future state was realized then we can execute a new examination from the second step.

Elaboration of New Intelligent Logistics Solutions:

In our explanation the intelligent logistics solutions those devices/(part)systems which are able to respond to changes of the external environment. It can be possible the more significant waste reduction with application and improvement of these solutions. The wastes’ reduction will be realized because of the reduction of the lead time of the tasks to be realized, respectively the increase of the optimized collaboration between the systems objects (source and drain objects, material handling equipment, staff, …, etc.). The optimized collaboration will result more efficient human and machine resource utilization. The more important logistics solutions in the production area are the followings:

- Intelligent identification devices

- Intelligent technological equipment

- Intelligent quality control

- Intelligent material handling equipment

- Intelligent warehouse

- Intelligent logistics systems

The industry 4.0 will have a relevant effect on the formation and actuation of the manufacturing systems. According to the forecast the next changes are possibilities:

- There can be realized the communication between the different devices and the central unit, respectively between the devices because of these the central control will be changed to decentralized central control in the future.

- The complex decision making will be changed to real time decision making with use of the simulation.

- The narrowly planned production systems will be changed to such production systems which are based on modularization.

- The passive parts will be changed to intelligent parts which will be able to influence their environmental with use of the pre-programmed information.

- There will be possible larger systems’ optimization if we will use such devices’ data which have network connection. Actually, there will be possible the optimized creation and actuation of a company’s total supply chain.

- New business models will be created with the processing of the huge amounts of collected data from the logistics systems